Internal Pressurization Bubble Testing System for ASTM F2096

Description of ASTM F2096 Bubble Leak Testing System

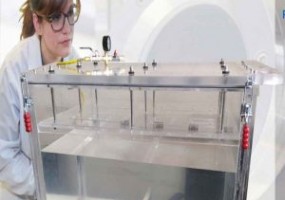

Internal Pressurization Bubble Testing System for ASTM F2096

This Internal Pressurization Tank System is designed to Detect Gross Leaks in Packaging by Internal Pressurization of test samples known as Bubble Test. The Burhani Internal Pressurization Bubble Testing System is manufactured according to ASTM F2096-11.The This test is sensititive to 250 micron holes. Bottles, Purses, Pouches, Boxes, Receptacles, plates, sacks, Jugs, Jars, Vials or anything else that can be puntured and submersed under water can be tested.

Bubble Test Video Square Chamber

Bubble test video Cylindrical Chamber

Burst Test Video

The Internal Pressurization Bubble Testing System gives test results within 10 to 30 seconds. Video is attached for your perusal. Another advantage is that it can help you identify and locate the spot rapidly and easily. This system is useful in lab and setting up new production line.

ASTM D3078 Standard Test Method for Determination of Leaks in Flexible Packaging by Bubble Emission

ASTM D6653 Standard Test Methods for Determining the Effects of High Altitude on Packaging Systems by Vacuum Method

ASTM D4169 Standard Practice for Performance Testing of Shipping Containers and Systems

ASTM D4991 Standard Test Method for Leakage Testing of Empty Rigid Containers by Vacuum Method

ASTM D5094 Standard Test Methods for Gross Leakage of Liquids from Containers with Threaded or Lug-Style Closures

ASTM F2096 Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test) – Using our optional adapter

System Features of ASTM F2096 System)

ASTM F 2096 Bubble Testing System

The system is fully assembled and ready to use. It features:

1. A Quality Built Clear Acrylic Tank.

2. Hinged, Lockable, and Transparent Top Loading Acrylic Lid

3. Overflow Safety Tank provision

4. 1-inch NPT Tank Drain Valve

5. 1-inch NPT Overflow Drain

6. Table Structure that holds the Clear Acrylic Tank robustly into place

7. Adjustable Height Feet, Or Lockable Casters